This section contains brief discussions of various

ballistics and shooting related topics as requested by correspondents. If you have a

question you have been trying to find an answer to (keep 'em ballistics and shooting

related--see your minister for the mysteries of life) email me by clicking

here and I'll do my best to find the

answer for you and if it is of general interest, publish it here. If you can contribute

additional input to one of the answers I'd would appreciate hearing from you too.

Check back frequently as new topics are always being added.

On this page:

What affects the mechanical accuracy of a rifle.

How can I make blank ammunition for

my rifle.

How good are "moly" coated bullets?

What kind of cleaning rod and accessories should I use?

How good are those "digital" scales?

Why won't my reloads chamber properly when

factory ammo works fine?

What does the term "standard

deviation" mean?

Besides

a reloading press and dies what equipment do you recommend to get set up for

reloading.

What does the target measurement "mean

radius" mean?

Is there anything that can be done to improve the

accuracy of standard commercial .22 rimfire ammunition?

Q. What affects the mechanical accuracy of a rifle.

A. Besides the factors in barrel construction and quality discussed on

"Page 2" of these Q&A the following are are the things that the bench rest shooters

worry about in no particular order.

Barrel/Action Alignment--If the center line of the bore is not square

to the locking lugs, or if the shoulder of the barrel does not bear evenly on

the action there will be a torquing effect on firing that is detrimental

to accuracy. Insuring that the barrel and action are "square"

ensures even forces on the barrel. Cleaning up action squareness is often

referred to as "blue printing."

Bedding of the barrel and action to the stock--Proper fit of the

action and barrel in the stock affect the vibration of the barrel and receiver

during the bullet's passage in the barrel. The action should snuggly fit the

recesses in the stock to prevent movement and torquing of the action. Part

of this is the application of proper and even force to the screws

holding the action to the stock. It should be noted that wood stocks swell

and shrink with changes in humidity which changes the bedding forces. This

is one reason that many bench rest shooters leave their action screws loose

during storage and transport and then tighten them to a specified torque just

before a match. A good inch-pound torque wrench is worth while investment.

Most barrels group their best when only the last inch or two of the chamber

end is bedded to the stock and the rest of the barrel free floated. This

also eliminates problems from uneven pressure on the barrel from stock warpage.

With this kind of bedding you should be able to slip a business card completely

around the barrel and slide it all the way to the beginning of the bedding

without interference.

Some barrels shoot their best with some pressure on the barrel near the fore

end. and then clearance all the way back to the chamber end bedding. It is

important to ensure that this pressure is even and applied only to the bottom of

the barrel. If your barrel is bedded in this manner and it suddenly stops

grouping well check the fore end area for warpage or uneven contact.

Cleanliness and freedom from fouling of the barrel--A barrel fouled

with powder, copper, or moly residue will lose its ability to shoot tight

groups. If you find that your groups are opening up, carefully and

completely clean your barrel with both a powder solvent and a copper fouling

remover. See "Page 3" of these

Q&A for a detailed discussion of barrel cleaning. Interestingly many

accuracy shooters find that only surface cleaning of the bore helps. Any

fouling in the pores of the steel, but not on the surface can remain and

contributes to barrel smoothness and consistency.

Condition of the muzzle crown and barrel throat--A nick on the barrel

crown at the muzzle end of the rifling can play havoc with a rifle's accuracy by

allowing the uneven escape of powder gases around the base of the bullet upon

bore exit. The squareness and smooth beveling of the muzzle crown can thus have

a great affect on accuracy, and many factory firearms have very poor

crowns. The muzzle needs to be absolutely square to the bore and the edge

of the crown needs to be smooth and even. Recrowning a friend's rifle

shrank the groups from several inches down to sub-moa.

A worn throat at the chamber end of the barrel will allow the bullet

to enter the bore at random angles thus destroying consistency. In

addition, the increasing free travel of the bullet as the throat wears changes

the pressure curve and velocity which can put the bullet's velocity outside of

the barrel's sweet spot as described on a previous page. While throat wear

can be compensated by seating the bullet further out, this may be precluded by

magazine feeding requirements.

Security of the sight mounting system--One of the most overlooked

factors when a rifle doesn't group well is looseness in the sighting system and

its mounts. Over my years in shooting I have come across countless

shooters who's scope rings had loosened on the receiver. Simply tightening

things back up brought the group size back to normal. I've even come

across new rifles with "factory installed" scopes with loose mounts

right out of the box.

Evenness of bolt locking lug bearing--Due to mechanical tolerances

sometimes the locking lugs on the bolt do not evenly bear on the receiver.

This cause a torquing effect when the rifle is fired which has a detrimental

effect on accuracy. This is one reason why precision shooters have their action

"blue printed" or trued when building a rifle. Locking lug

bearing can be checked by coating the rear of the bolt lugs with "Dykem"

marking fluid, closing the bolt, and then working the bolt several times while

applying pressure on the bolt face with a cleaning rod. If the unevenness

is slight the lugs can be lapped to provide even bearing.

Q. How can I make blank ammunition

for my rifle.

A. Blank ammunition for manually operated rifles

(not semi autos) is not difficult to make. Before going any further on

this topic two warnings.

First, NEVER, NEVER, NEVER take

the powder from GI .30-06 blanks to use in other calibers. The EC powder

used in those blanks was also used as a grenade filler and pressures can get out

of hand VERY quickly.

Second, do not attempt to use these home made blanks

with blank firing adapters on self loading firearms. Such blanks require a

very careful tuning of the load and you can get in trouble very fast if the hole

in the blank adapter is not correct.

Third, please review the the question on the dangers of blank ammunition on Page

1 of these Q&A pages before using blank ammunition.

The smokeless powders used for military blank ammunition such as EC, SR4990,

HPC-13, WC-814, WC-818 and similar are not available on the commercial market.

For 308 / .30-06 and other similar capacity cartridges try 12-20 gr of either RED DOT

or SR 4759, (the GI M82 long neck 7.62 mm blank has been loaded with 17.5 gr of

SR4759 and the "short neck" rosette crimp M192 blank with 21.5 gr of

SR4759) or 9 to 10 gr Unique (work up from the lower charge to get the desired results). You can

close the case mouth with a small piece of kapock or quilters batting and

a drop of shellac or you can use a special rosette crimp die available on

special order from RCBS, Hornady (#544590), and CH Tool & Die/4D (under

their "specialty dies" heading--they have a wide assortment of blank

making dies). Use a drop of shellac to seal the hole. The

rosette crimp helps with feeding.

For .223 blanks try 5 to 8 gr of Red Dot, with a rosette crimp sealed with a

little varnish.

If you want "big" blanks you can make .50 BMG blanks by using 44.5

gr of Hi-Skor 700X, and close the mouth with a rosette crimp or use a card wad

glued in place. 12 gauge blanks are easily made using 50 gr of FFG black

powder or Pyrodex topped with a 1/2" Styrofoam wad (cut using a brass

10 gauge case) that is seated firmly. Crimp the case as normally done.

Some folks have reported getting good results by using a sharpened case to

punch out pieces of 1/8" felt as a closure wad which are then sealed in

place with a drop of shellac and a light roll crimp. (You can also try

using a mild roll crimp or even using a small caliber die of the same basic case

size (such as a .243 for the .308 or .270 for the .30-06) to provide a reduction

in case mouth size.) Never use any hard material for the closure

wad as you will have a projectile capable of inflecting a serious wound.

Pistol caliber blanks can be made using a very

fast powder like Norma R-1, Vihta Vuori N310, or Hodgdon Titewad, or Red Dot. Start

with about 2 gr with a card or foam wad cut from a sheet of thin craft foam and work up to the desired noise level, but

don't exceed the maximum charge listed for a light bullet. You may have to

enlarge the flash hole to prevent primer setback.

If you need specialized blank cartridges in quantity for organizational or

theatrical use try contacting one of the surplus ammunition distributors or one

of the major commercial blank ammo producers such as the following

www.atlanticwallblanks.com/

www.joeswansonsmotionpictureblanks.com

www.duffysguns.com/BlankAmmo.htm

www.hbci.com/~nartron/prod12.html

** A SPECIAL CASE **

If you need reliable .30-06 blanks for honor guard use in the M1 Garand using

the GI issue blank firing adapter you can safely use 8.5 gr to 10 gr

of Unique with the CCI #34 (military hard cup) primer. Use the charge that

gives the desired noise level and functions the rifle. Use a rosette crimp

die (available from Hornady, RCBS, and CH) to close the case mouth and seal with a drop of lacquer. DO NOT USE ANY

WADDING!!!!! Note that the rifles need to be clean, properly lubricated, and the

gas port in the barrel needs to be centered in the opening of the gas cylinder

for things to function.

Q. How good are "moly" coated

bullets?

A. Bullets coated with molybdenum disulfide ("moly")

supposedly provide several advantages including potentially increased barrel

life, less fouling, less throat erosion, and the potential to get increased

velocities, but there seems to be little if any scientific

proof of these things. However, any possible benefits depend on two

things.

Barrel cleanliness - Barrels to be used with moly coated bullets must

be smooth and free from any copper fouling. Copper fouling will strip moly

from the bullets and cause severe moly fouling which if left in the bore can be

difficult to remove and in extreme cases can damage the bore.

Thickness of the moly coating - Early moly experimenters did not

understand the proper use of moly and did several things wrong. First, they

neglected to remove the sizing lubricant used in the bullet manufacturing

process from the bullets before coating them. This led to a lumpy moly

coating which fouled the bore. Second, they used too much moly which added

to the fouling process. Properly coated bullets should have a silvery

appearance and not a black or rough looking finish. Most current moly

coated bullets are properly done.

If you are currently getting good results with uncoated bullet there is

probably no

real reason to change unless you want to experiment.

There is currently research going on to incorporate moly in the powder rather

than putting it on the bullets which could result in much more consistent

results without the problem of moly caking in the bore.

For cleaning moly fouling the solvent of choice is Kroil Penetrating Oil

& Bore Cleaner. While it doesn't desolve it it gets underneath it and

helps to float it off.

While they were once the rage, most precision shooters no longer use moly

coated bullets.

Q. What kind of cleaning rod and

accessories should I use?

A. There are a myriad of cleaning rods on the market. Aluminum, brass,

steel, plastic coated, one piece, and multipart. It is easy to get

confused. If you are very careful with them, keep them clean (during and

after use), use a bore

guide, and clean from the receiver end when possible, you can probably safely use any

type of rod. However, I don't know why someone would use a brass rod when

using a copper solvent as they do slowly deteriorate from the copper solvent.

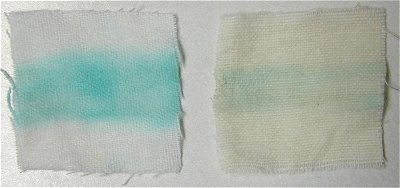

The photo below shows what happens when a brass rod is subjected to various

cleaners.

|

|

These new

patches were dampened with copper solvent and left in contact with a clean

brass cleaning rod for 1 minute. L to R: Marksman's Choice Copper

Remover, Marksman's Choice MC-7 Bore Cleaner. The non-contact area

of the MC-7 patch is

discolored from the MC-7 solution.

|

I do like the Tipton carbon fiber rods sold by Midway and the Bore-Stix rods

sold by Brownells and others, but confess that I have a number of Dewey

rods. In my opinion, the one piece steel rods are probably the best

though.

Rods made of soft(er) material can get particles of carbonized powder

residue and other crud imbedded in their surface. (When you lap a barrel

using a lead slug and abrasive compounds the steel barrel wears--not the lead

slug.) Remember to wipe your rods clean during and after use.

| Type |

Pro |

Con |

| Jointed rods (any material) |

Compact, easy to transport |

Edges of joints can trap scratch

producing residues; edges can nick throats and muzzles if used without a

guide; joints tend to come unscrewed and/or break at the joint. |

| Aluminum |

Light weight, inexpensive |

Aluminum oxide is a steel

cutting abrasive--Think about that! Abrasive particles can imbed in the

soft aluminum. |

| Brass |

Looks great |

Brass is soft and abrasive

particles can imbedded in the brass, brass slowly dissolves when used with

copper removing bore cleaner |

| Coated |

Looks safe |

Abrasive particles can imbed in

the plastic coating; solvents can work their way under the coating;

coatings tend to peel off. |

| Steel |

Abrasive particles won't imbed

in rod; strong and won't bend easily;

easy to maintain |

Expensive |

| Carbon Fiber |

Very stiff but light weight |

Expensive. While not as soft as

most coated rods, abrasive particles could still imbed in

the rod. |

For brushes use either the phosphor bronze brushes (with standard bore

cleaners) or the nylon brushes (with copper solvents). Have a good supply

of brushes on hand. I do not recommend stainless steel brushes

as there have been numerous reports from the precision shooting folks that they

can scratch the bore. For patches I recommend a properly fitting jag

rather than the old slotted tip as nothing but patch material can touch the

bore. Most commonly available jags seem to be made out of brass--which

seems strange if you will be using a copper solvent which will cause the brass

to deteriorate--or plastic which seems to have the annoying property of breaking

off just at the joint of the threads. Stainless steel jags are much more durable but

are hard to find in all calibers. At one time jags were available in aluminum

in a short "button" type (which, since they were covered with the

patch didn't have any abrasive properties in contact with the bore) but I

haven't seen them in a longtime. Outers use to make stainless steel jags in .22

cal (OUT40342), .270 cal (OUT40344), and .30 cal (OUT40346) but they don't seem

to list them any more.

Brownells is now offering the Dewey brand non-brass jags in both female

(Dewey rods) and male (standard rods) threading. Click on the links

below for more information.

Female

thread jags

Male

thread jag

Speaking of patches, don't be a cheapskate. Use decent quality patches

of the correct size to get maximum cleaning and prevent bore damage. The

few cents you'll save by making your own isn't worth it. I buy my patches

and brushes in bulk from Brownells and get worried if I have less than 500

patches and a half dozen brushes per caliber.

Q. How good are those "digital"

scales?

A. Digital? If it's digital it's gotta be

great, right? Wrong! While digital scales have their use and newer

digital scales are getting more reliable, there

are some serious caveats to be aware of.

First, to be as accurate and

repeatable as possible they all need to warm up for several minutes (as

long as 15 minutes with some brands) before using. Second, once they have been calibrated,

it they are moved to a colder or warmer area or if the ambient temperature

changes more than a degree or two they must be recalibrated.

Third, their design plays a big part in how good they are. The best units

have multiple load sensors instead of just one and average the readings from

each cell to give the displayed reading. Units with only one load cell can

suffer from inconsistent readings due to torque or friction related causes if the item

being weighed is not centered over the load cell. Fourth, they all exhibit

drift. That is, when used for a long period of time they may change their

reading for a given weight. I have seen some scales

develop 5% or more drift. Be safe! Check frequently! If

being used for more that a few minutes, you need to check them with a known

weight to ensure they are reading correctly, and if not they need to be

recalibrated per the manufacturer's instructions. Fifth, they need to be

used on a smooth flat surface that is free from static electricity. (To

eliminate static electricity you can wipe the work area with a dryer fabric

softener sheet.).

Also many designs will allow powder grains and "schmutz" to get

under the scale platform or load sensor which can cause all kinds of interesting

problems. Keep your scale clean and covered and calibrate it and check with a

range of known weights up at least 75% of the scales capacity to make sure

nothing is amiss.

Try the following with your digital scale.

1) Warm it up and

calibrate it according to the manufacturer's instructions. Then weigh a

bullet or some other known object repeatedly (say 10 times) with the object centered

in the scale pan. Then try the same thing with a mechanical balance beam

scale. You may be surprised just how inconsistent some digital scales can be, with some brands of scales varying ± .2 gr or more with the same test

object repeatedly measured.

2) Then repeat the test but place the object in

different corners

of the scale pan for each reading. It should be noted that dropping an

object to be weighed into the pan--as opposed to gently placing it in the

pan--can cause a wide variance in readings.

3) Turn on the scale and if possible defeat the automatic shutoff found on

many scales. Place a known weight on the scale and then check the reading

every minute for as long as possible. Repeat this test but weigh and then

remove and replace the test weight every minute.

(If you would like a copy of my scale test work sheet, click

here.)

These variances can cause

trouble with measuring powder charges for small capacity cartridges operating at

maximum pressures, not to mention the effect on very long range accuracy.

In my experience and that of a friend who is a long range precision shooter the

original Dillon/CED digital scales (which have 4 strain gauges) appear to be the most

consistent. However when loading for utmost accuracy or small capacity

cases use a regular balance

beam scale to weigh charges.

Speaking of balance beam scales, they need to be carefully used and stored

too. The fine, sharp, knife-edge pivot bearing surfaces are easily damaged

and sensitive to dirt on the bearing surface. Handle them gently and keep

them covered when not in use. They can also be affected by static

electricity.

Q. Why won't my reloads chamber

properly when factory ammo works fine?

A. This can be caused by several different

things. First, your sizing die may not be properly adjusted. Sizing

dies are generally designed to touch the shell holder of the press to achieve proper

resizing. However, many reloading presses have a little spring in their

frames when under stress and the die may not be making proper contact with

the shell holder and the shoulder of your bottlenecked case may not be getting

pushed back enough. In addition, the tolerances of the die may be off. The best way to adjust sizing dies is to use a case

gauge like those offered by Wilson, Dillon, and others.

These gauges are cut with a

very close tolerance "chamber" and by dropping in a sized case you can

see if the case is being properly sized. Second, if you are using military

brass there is a good chance that it has been fired in automatic weapons which

have generous chambers and which allow the brass to expand more than normal.

Standard sizing dies may not squeeze the base diameter of these over expanded

cases down far enough to allow easy chambering. The solution to this is to

use a "small base" sizing die which will size the case's base more

thoroughly. The same thing occurs in many pistol calibers fired in

Glock pistols. Glock chambers don't support the head of the case very well

at the bottom of the chamber mouth. This can result in a very noticeable bulge,

Many shooters gauge factory ammo for use in critical applications because

even the factory can have a bad day. If it passes the gauge test they then

actually run the ammunition through the firearm to ensure all is well.

I've have personally seen many rounds of factory ammo from all manufactures that

was out of spec or quality with problems ranging from deep seated bullets no

primer or upside-down primer, bulged cases or case mouths, and even a round with

the bullet upside-down. The moral of the story is CHECK EVERYTHING!

Q. What does the term "standard

deviation" mean?

A. "Standard deviation" is a

mathematical way of looking at the uniformity of some measurement. In

shooting, the term is used to show the consistency of weight or velocity

of a number of items. In simplistic terms it looks at how far

away from the average of all measurements each individual measurement is. If the standard deviation is

small, the measurements are tightly clustered around the average; if it is large,

they are widely scattered.

In

mathematical terms the

standard deviation of a set of measurements x1, x2,

…, xn, with the mean "x-bar" (the

"x" with the line over it) is defined as

the square root of the mean (average) of the squares of the deviations; it is usually

designated by the Greek letter sigma (s).

Luckily

modern chronographs and many calculators have built in routines for computing

standard deviation. Those interested in learning more are invited to

consult a statistical text book or one of the articles in some loading manuals

for more details.

Q.

Besides a reloading press and dies what equipment do you

recommend to get set up for reloading?

A.

I suggest the following additional equipment.

First you

don't need a fancy, expensive, progressive reloading press to get started. A simple

single stage press like the Lee, Lyman, or RCBS basic presses are all that is

needed as are standard dies. You don't need

the fancy "bench rest" or "competition" dies. Many

manufacturers have starter packages that include a basic press, dies, and

necessary accessories at a substantial discount.

-

Scale

(Your primary scale should be a balance beam scale and not a digital model.

Use the digital scale as a backup.)

-

Reloading

manual (I suggest the Lyman one to start with)

-

Case

gauge (for rifle calibers-to properly set your sizing die) See the tip above

on reloads not chambering.

-

Spray

type case lubricant

-

Powder

measure

-

"Loading

blocks" (can use cartridge box plastic inserts too) to hold cases in

process.

-

Dial

calipers (there are several in expensive ones) to check overall length and

case length

-

Case

trimmer.

-

Deburring

tool and a primer pocket cleaner.

-

Case

tumbler and cleaning media

-

A

chronograph and ballistics software

-

A

notebook (To keep records of what you do.)

-

Personal

patience and attention to detail.

In

addition, if you plan to reload military issue brass you will need either a

primer pocket reamer or a primer pocket swaging tool to remove the crimp

from around the primer pocket.

You

may notice the "chronograph." Why do I recommend one?

Because without it you have no idea what is actually happening, working up a

good load will take longer, and with actual velocity data you will be able to

compute your trajectory data using ballistics software.

I

would also add to this list a rifle rest and some medium sand bags to use

when testing loads.

Some

additional notes. For crimping I really like the Lee "factory

crimp" dies. For pistol calibers the die not only crimps to factory

specs it also contains a carbide ring to ensure that the finish cartridge meet

all dimensional specifications. In rifle calibers the crimp die utilizes a

compressible collet to create a very uniform crimp. Just be careful not to over

crimp. You want a snug consistent fit, not a crushed bullet.

Case

trimmers. There are numerous units out there running from about $15 to

$400 and all work. For a low volume reloader the simple hand held manual

Lee Trimmer is just fine. For the higher volume reloader the trimmer I

like best is the Trim-It unit from ACT-Coleman Machinery (eztrimit.com).

This nifty unit fits on an electric drill or drill press and is amazingly fast

and consistent. It uses interchangeable bushing (comes with .308 and .223)

and indexes off of the case shoulder. As with all, except the $400 Giarud

trimmer, you will probably have to chamfer the inside and outside of the case

mouth after trimming. Trim your cases after resizing the first time.

If

you are reloading for a single rifle, you don't have to full length resize your

brass. Use a neck sizing die instead or back out you full length sizer so

the case shoulder isn't touched You will get much longer case life and generally

better accuracy. Lee offers a very nice collet type neck sizing die.

As

to brands of dies and other equipment, the choice is yours as modern dies are

remarkably well made. My personal favorites are the Bonanza (Forester) BR

series for rifle calibers and RCBS and Lee for pistol calibers. I also

like the Dillon Carbide pistol sizers especially when using a progressive press.

Thgey have a rounded entry way that allows ti cases to aling with the hole

without manually tweaking them. While some

folks pooh-pooh the Lee dies as "cheap" I have found them to be

uniformly excellent and have several in odd ball calibers that I don't reload a

lot.. My only complaint is that all the expander plugs seem to need a good

polish with some 600 grit paper to smooth them up before use.

For

some goodies that will make your reloading easier, without breaking the bank, click

here.

Q.

What does the target measurement "mean radius"

mean?

A.

The "mean radius" is simply the average distance of all shots from the

center of the group. To compute the mean radius draw a horizontal line

just below the group and the measure the height of each hole above that line and

the average those measurements. Using a vertical line do the same thing

and average the distances. These two measurements will locate the center

of the group. Then measure the distance from the group's center to each

hole and average those measurements. The result is the "mean

radius." While not exact, the maximum spread (group size) is approximately

3 times

the mean radius.

Another

similar measurement (though not often heard of) is called the "figure of

merit." To find it, draw a line through the center of the lowest shot in

the group and then measure the vertical distance to the center of the highest

shot in the group. Do the same with the shot farthest to the left and

measure to the farthest right shot. Average these two measurements.

Both

of these measurement are seldom used outside of the military but are much better

indicators of ammunition consistency than group size.

Q. Is

there anything that can be done to improve the accuracy of standard commercial

.22 rimfire ammunition in my rifle?

A.

Industry specifications call for 3" or less 10-shot groups at 100 yards

(accuracy test barrel) using non-match ammunition but most lots will group well

below 2" with the better low velocity load lots getting into the 1.25 - 1.5 moa range.

There is no statistically significant difference in accuracy between plated or

unplated bullets. However, standard velocity non-match ammunition,

and match (which is generally standard velocity) group tighter past about 50

yards due the the HV ammunition going trans-sonic at about that range.

The first thing to do is to try several brands and see which one your particular

rifle likes. Then start sorting the ammunition. Rimfire shooters have discovered that the consistency of their ammunition can be

improved by sorting by weight of the complete cartridge and by rim thickness .

Weight sorting seems to give the best results with non-match ammunition. A handy gauge for checking rim thickness can be made by

drilling a hole in a small piece of steel about an inch long with a #1

drill--ideally a .227 hole should be bored but a #1 drill is close enough at

.228". A gauge for .22 WRM can be made with a "C" or

"D" size drill and a piece of metal about 1.4" long--ideally a

.244" diameter hole should be bored but a .242 "C" or a .246

"D" drill should work OK. If you have access to .22 rimfire chambering

reamers you can use these to make the gauges. There are also similar

commercial gages.

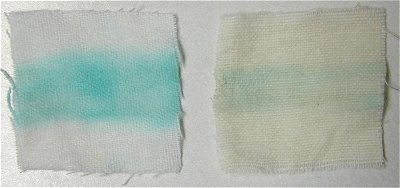

|

|

Rim thickness gauge.

This one was made from a

piece of a

drilled out.22 caliber barrel stub

|

To

use, drop the round into the jig and measure the length of the block plus rim

and sort cartridges in .001" increments. If you can accurately

measure your rifle's headspace matching rim thickness to headspace is a further

refinement and using rounds whose rim thickness is as close as possible to the

headspace seems to improve accuracy. In addition many shooters will then

further sort by the weight of the complete cartridge.

SAAMI specifications for rim thickness is .043" -

.007". for 22 rimfire ammunition, and .050" -.008" for

.22WMR ammunition, but I have measured rim thickness ranging from .034" -

.058" on .22 rimfire ammunition so apparently there can be considerable variation

outside of the official specification. SAAMI headspace measurements are

.043" (min) - .051" (max) for .22 rimfire and .050" (min) -

.056" (max) for .22WRM. If possible have the headspace adjusted to

.043 for .22RF and .050 for the WMR. (If you have a handy machinest you

can adjust your headspace for optimum performance. With bolt actions this

can be tricky but with blowback semiautos you can simply mill the bolt

face. A friend had his 10/22 bolt milled

to get .043 headspace and shrank his groups by almost 1/2 ".)

One other thing commonly overlooked

in .22 rimfire accuracy, though not ammunition related, is the

condition of the muzzle of the barrel. Many .22 muzzles are damaged

by improper cleaning (if they are ever cleaned) or by dings and dents. Be

sure your barrel is clean and consider having the muzzle of the barrel trimmed

square and then recrowned. Other than that one can also consider having

the barrel set back and rechambered as some rimfire chambers are pretty sloppy,

especially those in many inexpensive .22s.

Regarding

SAAMI "match" vs "sporting" chambers for .22 rimfire.

The basic difference is that match chambers are smaller in diameter (.2267"

vs .2307" at the breech, .2248" vs .227" at the mouth, and the

chamber body is shorter, .643" vs .818"). This has the effect of

causing the bullets in a match chamber to slightly engage the rifling upon

chambering. There are also several custom "match chambers which differ

mainly in chamber length and throat angle.

Please email comments to Fr. Frog by clicking

here.

| Back to Q&A Index | Ballistics Main

Page |

| Back to Fr. Frog's Home Page |

Disclaimer

As far as I know all the information presented above is

correct and I have attempted to ensure that it is. However, I am not responsible for any

errors, omissions, or damages resulting from the use or misuse of this information, nor

for you doing something stupid with it. (Don't you hate these disclaimers? So do I, but

there are people out there who refuse to be responsible for their own actions and who will

sue anybody to make a buck.)

Updated 2018-01-04