|

| 7.62 mm M984 |

This section continues the discussions of various ballistics and shooting related topics as requested by correspondents. If you have a question you have been trying to find an answer to (keep 'em ballistics or shooting related--see your minister for the mysteries of life) email me by clicking here and I'll do my best to find the answer for you and if it is of general interest, publish it here. If you can contribute additional input to one of the answers I'd would appreciate hearing from you too.

On this page:

Can you recommend a good basic

library of books relating to shooting?

What is a SABOT round?

What are the ballistics of modern US military rifle

cartridges?

What is the maximum range of shot from a shotgun?

How do you identify military explosive or

incendiary ammunition?

Why is there such a difference between the data in different loading

manuals?

Can I use hollow point "match" bullets for hunting?

Is tumbling loaded ammunition dangerous?

What is the proper procedure to clean a barrel?

Is there a special procedure for "breaking in" a new

barrel?

When I buy surplus ammunition how do I know it is really NATO

specification ammunition?

Q. Can you recommend a good basic library of books relating to shooting?

A. To quote an ancient master, "One cannot have too many books." However, the following list will provide you with a solid library. My thanks to the Gunsite Alumni Group for this list. Some of these books are classics on the subject and may be out of print or hard to find. They are worth the effort to locate.

African Rifles and Cartridges - John Taylor

Ammunition Making - George E. Frost.

Ballistics in Perspective - Mike LaGrange

Bullet Penetration - MacPherson

Cartridges of the World - Barnes

Cast Bullets, Col. E.H. Harrison

Competitive Shooting - A.A. Yur' Yev

Fast and Fancy Revolver Shooting - Ed McGivern

From Behind the Line - Jim Crews

Game Loads and Practical Ballistics for the American

Hunter – Bob Hagel

Handloading for Hunters – Don Zutz

Hatcher's Notebook - Julian Hatcher

Hatcher’s Book of the Garand,- Julian Hatcher

Jacketed Performance with Cast

Bullets, by Veral Smith

Modern Exterior Ballistics: The Launch and Flight Dynamics of Symmetric Projectiles

- Robert L. McCoy (advanced reading but the most up to date)

NRA Guides to Firearms Disassembly

Principles and Practice of Loading Ammunition - Naramore

Principles of Personal Defense - Jeff Cooper

Real World Survival - Walt Rauch

Reloading Manuals (any/all of the major, with the Lyman manuals a must have)

Scouting on Two Continents (Burnham)

Shotgunning; The Art and the Science - Bob Brister.

Sixguns - Elmer Keith

Small Arms of the World - Ezell

Some of the Answer: Carbine - Jim Crews

Some of the Answer: Pistol - Jim Crews

Some of the Answer: Shotgun - Jim Crews

Textbook of Pistols and Revolvers - J.S. Hatcher

The Art of the Rifle - Jeff Cooper

The Bullet's Flight From Powder to Target -- The Internal and External

Ballistics of Small Arms - F. W. Mann

The Complete Book Of Modern Handgunning by Jeff Cooper

The Complete Guide to Handloading - Sharpe

The Defensive Shotgun - Louis Awerbuck

The Gun and its Development - W.W. Greener

The Handbook of Commercial Bullet Casting – Paul B. Moore

The Hunting Rifle - Townsend Whelan

The Modern Gunsmith (Vol 1 & 2) - Howe

The Modern Technique of the Pistol - Greg Morrison

The Secrets of Double Action Shooting - Bob Nichols

Understanding Firearm Ballistics Basic to Advanced Ballistics Simplified,

Illustrated and Explained, by Robert A. Rinker

I would also recommend copies of the military TMs on any military or military type firearms you may own.

Q. What is a SABOT round?

A. A Sabot round (pronounced sah-bow') from the French for "shoe" is simply a cartridge that utilizes a smaller than bore diameter projectile held in a bore diameter sleeve. The use of this technique allows higher velocities than normal since the projectile is much lighter than the round's standard projectile and it still has a large base area for the propellant gases to push against. It also provides ballistic advantages over simply using a very light weight bore diameter projectile since the smaller diameter projectile will have a better ballistic coefficient and sectional density for a given weight. The most common commercial uses of this concept are in the Remington Accelerator rounds which fire a 50gr - 55 gr .22 caliber bullet from some common .30 caliber rounds and the new saboted 12 gauge slugs which fire a nominal .45 caliber projectile of about an ounce in weight which give better ballistics that a conventional shotgun slug.

|

| 7.62 mm M984 |

The concept is widely used in military ammunition where the higher velocities and kinetic energy obtainable can be put to use in armor defeating rounds by firing hardened projectiles. Often referred to as SLAP (Saboted Light Armor Penetrator) rounds they are used in numerous calibers from 7.62 NATO through the famous 120 mm tank canon "dart" and the concept has been experimented with in rounds up to the 16" naval canon. A 13" saboted projectile with a maximum useful range for the 1,384 pound projectile of over 73,000 yards (41 miles) was tried. There was also an 11" round considered that would have thrown a 650 pound projectile 175,000 yards (almost 100 miles).

|

| M829A1 120 mm APFSDS "dart" separating from its SABOT |

Q. What are the ballistics of modern US military rifle cartridges?

A. The trend has been for higher velocities and lighter bullets. However, it is interesting to note that for long range precision that everyone uses a medium bore cartridge (.30 cal or larger) with a heavier than normal bullet. In addition more and more consideration is being given to returning to a medium bore cartridge for better terminal effect. The table below shows the approximate ballistics of 20th century US military rifle ammunition. A sight height of 1" is assumed, with the exception of the 5.56 mm ammunition which uses the 2.5" sight height of the M16 rifle, and a zero range of 300 yards (typical GI combat zero) is used.

![US rifle caliber cartridges [18k jpg]](uscart.jpg) |

| US rifle

caliber cartridges L to R: .45-70, .30-40, .30 M2, 7.62 mm NATO, 5.56 mm NATO |

Interestingly, note that the bullet 's trajectory for the four modern rifle cartridges is very similar at rages of 400 to 600 yards and that the "effective range" for the 7.62 mm and 5.56 mm ammo and rifles is stated as about 460 meters (500 yards). The muzzle velocities are from published sources and the ballistic coefficients used for the .45-70 and .30-40 Krag bullets were those of equivalent current commercial bullets (G1). A G7 program was used for the 7.62 mm and 5.56 mm cartridges. The .30 M2 data was derived by matching BRL data obtained at 2700 f/s and then using 2750 f/s which is closer to the actual velocity of this load.

| Range | .45-70 500 gr |

.45-70 405 gr Carbine |

.30-40 Krag 220 gr |

|||

| Velocity | Trajectory | Velocity | Trajectory | Velocity | Trajectory | |

| 0 | 1310 | -1.0 | 1150 | -1.0 | 2000 | -1.0 |

| 100 | 1200 | 24.9 | 1050 | 32.6 | 1760 | 11.6 |

| 200 | 1110 | 26.6 | 980 | 34.6 | 1560 | 13.0 |

| 300 | 1040 | ± | 920 | ± | 1380 | ± |

| 400 | 990 | -58.7 | 870 | -75.5 | 1230 | -31.5 |

| 500 | 940 | -153 | 830 | -197 | 1110 | -85.9 |

| 600 | 910 | -287 | 790 | -369 | 1030 | -169 |

| 700 | 860 | -462 | 750 | -597 | 968 | -284 |

| 800 | 870 | -684 | 720 | -890 | 918 | -436 |

| 900 | 810 | -955 | 680 | -1240 | 855 | -630 |

| 1000 | 780 | -1280 | 650 | -1680 | 836 | -896 |

| Range | .30M1 Carbine 110 gr |

.30 M2 150 gr |

7.62 mm NATO 147 gr |

5.56 mm M193 55 gr* |

5.56 mm M855 NATO 62 gr* |

6.8 x 43 mm 115 gr* |

||||||

| Velocity | Path | Velocity | Path | Velocity | Path | Velocity | Path | Velocity | Path | Velocity | Path | |

| 0 | 1950 | -1.0 | 2750 | -1.0 | 2750 | -1.0 | 3250 | -2.5 | 3050 | -2.5 | 2675 | -2.5 |

| 100 | 1540 | 17.0 | 2530 | 5.2 | 2530 | 5.1 | 2850 | 3.1 | 2730 | 3.4 | 2404 | 4.9 |

| 200 | 1230 | 20.1 | 2310 | 5.9 | 2320 | 5.9 | 2480 | 4.4 | 2430 | 4.7 | 2150 | 6.2 |

| 300 | 1040 | 0 | 2104 | 0 | 2110 | 0 | 2140 | 0 | 2150 | 0 | 1910 | 0 |

| 400 | 933 | -51.8 | 1903 | -13.6 | 1920 | -13.5 | 1830 | -12.0 | 1890 | -12.1 | 1685 | -15.8 |

| 500 | 854 | -144 | 1690 | -37.0 | 1740 | -36.7 | 1540 | -34.8 | 1640 | -34.4 | 1471 | -43.9 |

| 600 | 785 | -283 | 1500 | -72.5 | 1570 | -71.3 | 1270 | -73.4 | 1410 | -69.6 | 1271 | -88.3 |

| 700 | 723 | -480 | 1330 | -124 | 1400 | -120 | 1060 | -136 | 1200 | -123 | 1098 | -154 |

| 800 | 667 | -742 | 1190 | -194 | 1250 | -187 | 981 | -230 | 1050 | -204 | 1016 | -248 |

| 900 | 615 | -1080 | 1080 | -290 | 1100 | -278 | 919 | -357 | 986 | -317 | 963 | -377 |

| 1000 | 568 | -1520 | 1010 | -415 | 1040 | -402 | 863 | -521 | 934 | -463 | 917 | -542 |

| * Velocity

from a 20" bbl M16. From a 14.5" M4 velocities are about

100-125 f/s less and 1000 yd drop is about 10" more * Velocity from a 16" barrel. From a 20" barrel velocity is about 40 f/s greater and 1000 yd drop is about -524 |

||||||||||||

Q. What is the maximum range of shot from a shotgun?

A. Round projectiles, because of their high drag to diameter ratio, lose velocity rather quickly. US Army firing tables list the maximum range of 00 buck as 600 yards and that of #8 and #9 shot as 230 yards and 210 yards respectively. For round balls at relatively low velocity the maximum range can be approximated by "Journee's Rule" which states that for velocities typical of shotguns and muskets the maximum range in yards is equal to 2200 times the diameter in inches. Using that rule we get the following.

| Round Projectile Maximum Ranges | ||||||

| Shot Size | Diam (in) |

Max Range (yd) |

Shot Size | Diam (in) |

Max Range (yd) |

|

| Round Ball | .645 | 1420 | 1 Buck | .30 | 660 | |

| Round Ball | .610 | 1340 | #4 | .13 | 286 | |

| Round Ball | .545 | 1200 | #6 | .11 | 242 | |

| Round Ball | .38 | 850 | #7½ | .095 | 209 | |

| 00 Buck | .33 | 726 | #8 | .09 | 198 | |

| 0 Buck | .32 | 704 | #9 | .08 | 176 | |

As you can see the maximum range comes out a little high for 00 buck and a little low for #8 and #9 shot sizes compared to the firing table data, but it is close enough for most purposes. For steel shot with its lower sectional density the maximum range will be about 25 percent less that stated for the same diameter shot. While not "shot" Forster type shotgun slugs of any gauge have a maximum range of about 820 yards.

Q. How do you identify military rifle caliber explosive or incendiary ammunition?

A. Military rifle caliber explosive or incendiary ammunition is pretty much obsolete and is not very common in modern loadings. Because of its general age such ammo must be considered hazardous to shoot and no attempt should be made to pull its bullets, especially with an inertial bullet puller. Keep in mind that in many jurisdictions the possession or use of such ammunition, except for collector's samples, may be illegal. The chart below lists some of the more commonly encountered explosive or incendiary rounds and their identifying marks. Remember that different identifying marks do exist so treat any unknown ammunition, especially ammunition with colored markings, with extreme caution.

| Rifle Caliber Explosive Ammunition | |

| 6.5 x 52 mm Carcano | Small hollow point on bullet and bullet has a blunt conical point |

| 7.62 x 54 mm Russian | Red bullet tip Red on green tip bullet tip |

| 7.7 mm Japanese | Flat tipped bullet and violet primer annulus |

| 7.7 mm Japanese Rimmed (.303 Brit) |

Violet primer annulus |

| 7.92 x 57 mm German | Chrome bullet tip Silver bullet tip Bottom half of bullet stained black 3/4 of bullet tip blackened Some variations my also

have black primer |

| Rifle Caliber Incendiary Ammunition | ||||

| 6.5 x 52 mm Carcano | Sharply pointed bullet (Hard to tell from AP round) |

7.7 mm Italian (.303 Brit) |

4 holes near bullet tip and/or blue bullet tip | |

| 7.5 mm French | Blue bullet tip and annulus | .303 British | Blue bullet tip and/or blue primer annulus and "B" in head stamp |

|

| 7.62 x 54 mm R Russian | Violet on red bullet tip Black on red bullet tip |

US .30-06 (7.62 x 63 mm) | White bullet tip Silver bullet tip Blue bullet tip |

|

| 7.62 x 39 mm Russian | Red bullet tip Black on red bullet tip |

7.92 x 57 mm German | Entire bullet blackened and black primer annulus Black Primer Red primer annulus and red stripe on case head Black primer annulus Yellow primer annulus or yellow tip |

|

| 7.7 mm Japanese | Deep red band at case mouth | Intentionally left blank | Intentionally left blank | |

| 7.7 mm Japanese Rimmed (.303 Brit) |

Green primer annulus | Intentionally left blank | Intentionally left blank | |

Q. Why is there such a difference between the data in different loading manuals?

A. The reason for the differences is because each gun is a different item from the next. Minute differences in bore and chamber size due to manufacturing tolerances and wear on the bore and chamber reamers all contribute to the differences, as do barrel length and conditions where the loads were developed and lot to lot variations of the components used. Never start with the maximum load listed. Always drop the charge weight at least 10 percent to start but never go below the minimum listed load because erratic burning of the powder can occur.

Q. Can I use hollow point "match" bullets for hunting?

A. Hollow point bullets (whether for rifle or pistol) are designed to provide rapid expansion while soft points are designed to provide deeper penetration before expansion, but that performance can vary based upon the design of the bullet and the impact velocity. Hollow point "match" bullets are generally not designed to expand and should not be used for hunting. (A note here is that several OTMs will fragment at standard velocities but unless you have determined this to be the fact with your bullets I would avoid using them for hunting.) While at higher impact velocities they sometimes expand their performance is not consistent enough to be counted on. They are of the hollow point design simply because a bullet constructed with the opening of the jacket at its tip it is easier to make more consistent in base shape and concentricity--an important consideration for match use.

Many manufacturer provide a comparable bullet(s) designed specifically for hunting use that can pretty much be interchanged with their match bullets and which duplicate the match bullet's ballistics out to reasonable hunting ranges. The slightly lower accuracy potential is of no consequence in the field and many current hunting bullets are capable of match accuracy thanks to improved manufacturing processes.

Q. Is tumbling loaded ammunition dangerous?

A. Short term tumbling will have no real affect on loaded ammunition, but extensive tumbling can cause the breakdown of the powder grains. This would have two major effects. First, smaller grains will ignite more quickly than larger grains, and second the deterrent coating on the outside of the grains may be rubbed off and will be absent from any fractured edges which will cause the powder to burn more quickly raising pressures.

Tests run some years ago by a commercial entity did indicate that potentially dangerous changes in powder charge burning characteristics do take place after PROLONGED periods in either a vibratory or a tumbling cleaner.

The key word here is prolonged. Many manufacturers of ammunition do a final cleaning of their product either by tumbling or a vibratory process before boxing it for shipment. In no case is this allowed to exceed more than just a couple of minutes. The intent is not so much to "polish" but to remove any traces of contaminants which might in time leave marks on the finished product. There seems to be a consensus among the ammunition manufacturing engineers that a minute or two of vibratory cleaning has no discernable effect on burning rates, especially for loads that are compressed, or nearly so. However, all have emphasized the need for EXTREME CAUTION not to overdo the process.

They also pointed out that there is a considerable difference in effect on the powder charge depending on whether the process is by "tumbling" or "vibrating." It would appear that tumbling has less effect on the powder than vibrating, though this is mostly a matter of degree. The admonition to use EXTREME CAUTION to ensure that the process never exceeds a couple of minutes applies equally to either process.

Ideally you should do your reloading after an extensive cleaning of the empty brass so

any cleaning after loading is merely to remove traces of lube or to keep fingerprints from

staining after a couple of months storage. A two stage process is recommended. One minute

or so in a fairly abrasive cleaner with a tiny bit of solvent added to it to remove any

traces of lube left on the brass, followed by one minute or so in clean corncob media to

remove any traces of abrasive. Religiously follow several basic rules: use only a small

amount of solvent and do the cleaning in a well ventilated area; change your media

frequently, never letting it "load-up" with lube; and never "let it run

while you do something else" and run the risk

of letting it run too long and altering the burning rate of the powder.

Q. What is the proper procedure to clean a barrel?

A. Ah! Cleaning barrels. More blood has been spilled on this topic than on politics and religion combined.

Every "expert" seems to have their own special and often complicated procedure for cleaning but when it comes down to scientific tests more barrels have been ruined by over cleaning than by shooting. As far as accuracy goes, there may be some advantages to special cleaning procedures for the bench rest shooter with a finely made barrel, and where thousandths of a inch can make or break a match. But for everybody else extremely complicated procedures are probably a waste. I have never seen any scientific documentation showing the superiority of a particular cleaning method, just unfounded opinions. The biggest problem with barrels is usually copper fouling and not general crud. If your accuracy starts to drop off try removing the copper fouling. One thing to note. In order for the cleaning solutions to work they must thoroughly wet the bore.

I recommend the following guidelines for barrel care.

General Cleaning - Unless the gun is brand new I use the following procedure to remove powder or moly residue. (Note: If you are using a jag rather than a slotted patch tip you won't be able to pull the patches back through the barrel. Just take it off the jag, pull out the rod, and reinsert it.)

1) Run a thoroughly solvent wetted (but not drippy) patch through the bore once. (Push it through the bore and out--do not pull it back through--to prevent any loose "gunk" from getting in the breech.). The best way to do this is to wrap a patch around a nylon bore brush and the saturate the patch. This gets a lot more solvent onto the bore surface than just wetting a patch. Let it sit for a minute or two. If you have a gas operated firearm ensure that the gas port is "up" to prevent things getting into the system.

2) Wet a bore brush and push it completely through the bore and then pull it fully back. (Don't reverse while the brush is in the bore.) Repeat about 5 times. Let it sit for about a minute.

3) Run a dry patch through the bore once. (Push it through the bore and out and do not pull it back through.)

4) Run a thoroughly solvent wetted (but not drippy) patch completely through the bore and then pull it fully back, 5 - 10 times.

5) Repeat step 4, until patch comes out clean and then push a dry patch through the bore and dry the chamber area.

6) There is no need to oil the bore for storage unless it is undergoing long term storage or conditions are severe.

For a brand new gun, before I fire it I run a very lightly dampened patch through the bore and chamber, followed by several dry patches to remove any residual oils.

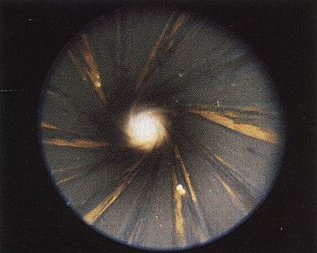

|

| If you can see

copper like this in the bore you really need to get to work! |

Copper Removal - The procedure for removing cooper fouling is similar. After removing powder fouling, etc. as described above, proceed as follows.

WARNING! - USE A NYLON BRUSH

AND PLASTIC OR OTHER NON-BRONZE JAGS WITH

COPPER SOLVENTS.

DO NOT USE A BRONZE

BORE BRUSH OR JAGS.

Brownells is now offering the Dewey brand non-brass jags in both female (Dewey rods) and male (standard rods) threading. Click on the links below for more information.

Female thread jags Male thread jags

1) Run a patch thoroughly wetted (but not sloppy drippy) with copper removal solvent through the bore once. (Push it through the bore and out--do not pull it back through to keep copper solvent out of the action.) For gas operated semi autos keep the gas port on top to prevent copper solvent from getting into the system. Repeat with a second wet patch but scrub the bore in short strokes, and then let it sit for 5 - 10 minutes.

2) Run a nylon brush wetted with copper solvent through the bore several times taking care not to get the solvent in the action or gas system.

3) Run a dry patch through the bore once. (Push it through the bore and out and do not pull it back through.)

4) Repeat steps 1, 2, & 3 until the patch comes out clean and free from green copper fouling and there is no visible fouling in the bore. Remember--with ammonia solvents, if the patch is green, it ain't clean. After the first one- way pass you can "scrub" the bore with wet patches with short back and forth strokes the length of the barrel for each repetition.

5) Run a a couple of regular bore cleaning solvent wetted (but not drippy) patches completely through the bore several times to remove any copper solvent.

6) Run a dry patch through the bore once or twice.

There is no need to oil the bore for storage unless it is undergoing long term storage or conditions are severe.

For Really Fouled Barrels

If the barrel is badly copper fouled and needs lots of solvent to work try this trick. Wrap a patch around a bore sized nylon brush and saturate the patch with copper solvent and run through the bore several times. The patch/nylon brush combo holds more solvent than a patch on a jag and wets the bore mote thoroughly.

If your bore looks like a copper tube (shame on you) you might want to try Outers "Foul Out" electrical system or the homemade equivalent which removes copper and moly fouling by a reverse plating process. This little device is fantastic. You won't believe the crud that will come out.

As long as you don't do a "Rambo rattle battle" while shooting, normal cleaning at the end of each shooting session should do just fine and there is no reason to have to clean the bore after "x" number of rounds unless accuracy is suffering.

Q. Is there a special procedure for "breaking in" a new barrel?

A. This is another topic of great controversy! Very elaborate procedures have been put forth by many folks for the so called "breaking in" of a new barrel, ranging from lapping the barrel with polishing compounds before use, to shoot one/clean for the first 20 to 50 rounds, or shoot one/clean, shoot two/clean, shoot three/clean, etc. It is claimed that these procedures help to smooth the bore's surface by allowing the surface of the bore to be smoothed without getting the pores of the steel filled with copper residue. This contributes to easier future cleaning and slower fouling. However, whether or how much these procedures are needed depends upon the original smoothness of the barrel. I have shot several rifles with extremely smooth (hammer forged) barrels that have, without any special breaking in, exhibited less copper fouling and were easier to clean than barrels broken it with complicated procedures.

The procedure most often recommended with a new barrel is to clean the bore with bore cleaning solvent and a cooper solvent as above. Then fire one round and clean the bore with a copper removing solvent--not with just regular bore cleaner. Fire another round and clean with copper solvent. Repeat this process until you don't see indications of copper on the patch--this usually take 10 to 15 shots. Some people then continue with a shoot 1, clean; shoot 2, clean; shoot 3, clean; up to to 10 or 15 rounds The bore should then be significantly smoother, easier to clean, and less prone to foul. If you continue to see copper after 10 to 20 shots with this routine it may be necessary to have the bore lapped (unless you are very patient).

As far as accuracy goes, as with cleaning methods I have never seen any documented scientific data that any such breaking in has any better practical effect on accuracy or the life of a barrel than just shooting and cleaning using normal cleaning procedures. For the bench rest shooter with an extremely high tolerance finely made barrel, where hundredths of a inch can make or break a match there may be some slight accuracy advantages to special break in procedures. But for everybody else, extremely complicated procedures are probably a waste of time. But if it gives you confidence use whatever break in procedure you feel comfortable with. However, if the barrel is very rough, manually lapping or "fire lapping" (the firing of abrasive coated bullets) the bore to remove machining marks makes some sense. Most folks I know simply clean a new barrel before firing to remove any preservatives and then again after the first 20 or so rounds. Then they go to their normal, after shooting routine. Just don't engage in rapid fire (generally good advice) until you've put some rounds through the bore.

Q. When I buy surplus ammunition how do I know it is really NATO specification ammunition?

A. The North Atlantic Treaty Organization

standardized ammunition specifications are to ensure interoperability and trajectory matching

of ammunition produced by its various members. Ammunition made for military use to these

specifications by member countries and so certified by the manufacturer is marked

with the NATO "cross and circle" ![]() symbol.

symbol.

|

|

NATO headstamp |

There are three things to keep in mind. First, for small arms, only 9 mm (9 x 19 mm), 5.56 x 45 mm M855/SS109 type with the 62 gr green tipped bullet or the equivalent M856/L110 orange tipped tracer ammunition, and .308 (7.62 x 51 mm) small arms ammunition are made to NATO standardization specifications. Second, while ammunition of the above calibers can be made to the NATO specifications by a manufacturer it can not properly be called "NATO" ammunition without the certification symbol on it. Such marking is done as a headstamp on small arms ammunition and as a headstamp and a painted marking on larger ammunition. Third, it may be that "surplus" ammunition, while manufactured to NATO standards may have been rejected for military use because the lot failed to meet the standard completely or the ammunition became detached from its original container that carried a lot number.

There is some 62 gr 5.56 ammunition being marketed from various sources that does not have the green tip, the steel penetrator, nor the NATO mark, that is being marketed as SS109/M855. This is NOT M855 NATO ammunition and should be correctly called 62 gr Ball 5.56 ammunition. Also note that there is no such thing as .223 (5.56 x 45 mm) M193 type (55 gr bullet), .30-06, .45 ACP, nor "Match" NATO specification ammunition.

Please email comments to Fr. Frog by clicking here

| Back to Q&A Index | Ballistics Main Page |

| Back to Fr. Frog's Home Page |

Disclaimer

As far as I know all the information presented above is correct and I have attempted to ensure that it is. However, I am not responsible for any errors, omissions, or damages resulting from the use or misuse of this information, nor for your doing something stupid with it. (Don't you hate these disclaimers? So do I, but there are people out there who refuse to be responsible for their own actions and who will sue anybody to make a buck.)

Updated 2019-03-22