|

|

16" HE projectile with full charge of powder bags, and shipping containers for powder bags |

This section continues the discussions of various ballistics and shooting related topics as requested by correspondents. If you have a question you have been trying to find an answer to (keep 'em ballistics or shooting related--see your minister for the mysteries of life) email me by clicking here and I'll do my best to find the answer for you and if it is of general interest, publish it here. If you can contribute additional input to one of the answers I'd would appreciate hearing from you too.

On this page:

What are, and what are the advantages

of, the various methods of making a gun barrel?

What is the difference between all of those .30 caliber

"magnum" cartridges?

Just how effective were the 16" guns on

the Iowa class battleships?

What is the performance of the "silver bullet"

120 mm rounds used on the Abrams M1A1 and A2 tanks?

How do you use a collimator to zero your rifle?

What affects the

accuracy of ammunition?

What is the difference

between a roll crimp and a taper crimp?

Can you suggest some reduced charge

practice loads for my hunting rifle?

Just how much accuracy is "enough?"

Q. What are, and what are the advantages of, the various methods of making a gun barrel?

A. The four common methods of barrel making are: hook-cut, broached, button rifled, and hammer forging. All start with a drilled and usually polished hole in the steel barrel stock. With cut rifling, a tool which contains a hooked cutter is pulled through the bore numerous times and indexed after every stroke to produce the rifling. With broaching all the grooves are cut at once by means of a long progressively stepped cutter that is pulled through the barrel. Button rifling is done by forcing a carbide tool containing the rifling relief through the bore. In the hammer forging process the barrel and rifling are formed by literally hammering a drilled blank over a mandrel which contains the rifling imprint and frequently the finished chamber.

The hook process, because of the fact that each groove is cut separately, (20 - 30 passes are generally needed for each groove) is a slower process but the exact rate of twist can be very accurately controlled. The broaching process is much faster because everything is cut at the same time and is frequently used for high volume military production but gives a somewhat rougher surface than cut barrels. The button process while it is fairly fast and generally produces a smoother finish than either the hook or broaching process does not provide as uniformly a controlled twist. Hammer forging can provide both rapidity of production and a very smooth finish (especially with a pre-polished hole in the blank) but it requires large and very specialized equipment to do. It also generally produces a barrel which becomes slightly tighter toward the muzzle which can increase velocity if the taper is sufficient. (See "Page 2" of these Q&A pages for more detail on this effect.) The hammer forged and button cut types can provide very smooth (and thus less prone to foul) bores but lapping can produce an excellent surface in the other types also.

As to which is "better," excellent barrels can be made by all four processes and ultimate accuracy doesn't seem favor one type or another. Cut rifling is favored for most industrial and experimental work because it is possible to obtain a wide variety of rifling forms, rates of twist , and bore sizes with only minimal tooling changes. It is also possible to pre-contour the barrel before drilling and reaming which reduces the risk of warpage or changes in bore diameter which can occur when a button cut is contoured after rifling or a hammer forged barrel is not profiled in the hammering process but after the fact.

Q. What is the difference between all the new .30 caliber "magnum" cartridges?

A. Good question--and one that a lot of people ask. There are a lot of the "300 magnum" cartridges around. Why? For the same reason there are so many similar cartridges in other calibers--to make money! (After all everyone knows that "mine is better than yours.") The table below gives the ballistics of some of the more common rounds along with the good old .30-'06 using 180 gr bullets. Data is from published ballistics and based on or corrected to a 24" barrel to keep things in proper comparison. As you can see, while there are a few with major differences most are hard to tell apart and nothing you hit with them will know the difference.

| 180 gr Bullet | ||

| Cartridge | Velocity | Notes |

| .30-'06 | 2700 | |

| .30-'06 Hornady Light mag | 2890 | |

| .300 H&H | 2880 | The "original" magnum |

| .300 Winchester | 2960 | Probably the most popular |

| .308 Norma Magnum | 2980 | |

| .300 Weatherby | 3190 | |

| .300 Remington Ultra | 3250 | Non belted case |

| .300WSM | 2950 | |

| .30-.378 Weatherby | 3450 | Based on the HUGE .378 Weatherby case and not the H&H case. |

If we discount the esoteric .30-.378 and the Remington Ultra-Mag and the old .300 H&H there is only a 240 f/s difference between the popular .300 magnum contenders (and the Hornady .30-'06 Light Mag is just about the old .300 H&H) and game won't know the difference. While at the high end there is a difference in trajectories at long range (past 300+ yards) with higher velocities the fact is that vast majority of game is taken at much shorter ranges--in spite of all those claims.

Q. Just how effective were the 16" guns on the Iowa class battleships?

A. Using a full powder charge the mighty 16"/50 caliber guns of the Iowa class battleships could throw the Mark 8 2700 pound AP projectile about 42,000 yards with a muzzle velocity of 2,450 f/s and the 1,900 pound Mark 13 "HC" explosive round about 41,000 yards with a muzzle velocity of 2,690 f/s. Velocity deviation of the ammunition was under ± 10 f/s for new or rebagged powder. [Full charge with the AP round was about 660 pounds of powder.] Chamber pressure was 37,000 - 40,000 psi.

The AP projectile carried a charge of only 41 pounds of ammonium picrate but it would penetrate 30 feet of high density reinforced concrete. The explosive round carried a charge of 153 pounds of ammonium picrate and fused for surface burst would clear an area 200 yards in diameter. With delayed fusing they would dig a crater 20 feet deep and 50 feet wide.

An accuracy test fired on 23 November, 1987 by the USS Iowa (BB 61) using the AP projectile, gave a pattern size (shot displacement on the ground) of 219 yards in diameter (15 rounds, fired 5 rounds from one barrel of each turret) at a range of 34,000 yards. (1 MOA is 1.044 inches per 100 yards so at 34,000 yards 1 MOA is 340 x 1.044 or 355 inches (9.86 yards), so we are talking about a 22 MOA 15-shot group.) However, that's not bad from a floating gun platform using ammunition and powder manufactured in the late 1930s and 1940s and fired from different barrels at a target over 19 miles away.

As an interesting footnote to history, besides the AP and standard explosive rounds, two "improved conventional munitions" (ICM) rounds were adopted in the late 1960s. They carried either 400 M43A1 wedge grenades (Mark 144/145) or 666 shaped charge bomblets (Mark 146). A nuclear projectile with a kiloton range warhead, designated Mark 23, was developed, tested and adopted in 1956. It was available until 1961 . A subcaliber saboted round was also under development at one time. It utilized a spin stabilized 13" projectile weighing 1000 pounds at a design velocity of 3600 f/s and a range of 70,000 + yards.

|

|

16" HE projectile with full charge of powder bags, and shipping containers for powder bags |

By the way, in naval parlance the "50 caliber" in the designation 16"/50 caliber means that the barrels are 50 "calibers" long, or 50 x 16" long--about 67 feet.

Q. What is the performance of the "silver bullet" 120 mm rounds used on the Abrams M1A1 and A2 tanks?

A. The actual armor defeating capabilities of the M829 APFSDS-T (Armor Piercing Fin Stabilized Discarding Sabot-Tracer) 120mm rounds as fired by the M1 Abrams tank are classified and have never been released. However, they will reportedly kill any known main battle tank in the world with one shot. The original M829 threw a 9.41 pound (that's 65,870 grains), 1.06" diameter, 24" long, depleted uranium "dart" at 5480 f/s! The A1 version fired a 10.78 pound dart at 5170 f/s and the current A2 version throws a slightly longer (30") but skinnier (.8") 10.85 pound dart at 5512 f/s. Operating pressures of the M829 series are between 74K psi and 96K psi depending on the particular variant. Muzzle velocity is within ± 78 m/s (256 f/s) between 0 and 120 degrees F (-18 to 49 degrees C). The nose of the "darts" is protected by a ballistic wind screen and the tip shape varies, being chisel shaped for the A2 version.

The "effective" range is listed as 3000 meters (limited mainly by group size) but one round killing hits have been obtained at close to 6000 meters and reported accuracy is sub minute of angle. The extreme range of the M829A2 is close to 70 miles when fired at 55 degrees elevation. The depleted uranium "dart" uses its 4 million plus foot pound of energy to literally burn its way through armor. The thermal flux at the point of impact is estimated at 1 million degrees. The DU is pyrophoric, that is, self incendiary, and will ignite anything within the target as well as producing a lethal barrage of fragments from its penetration.

Because of the M829's extreme maximum range a shorter ranged practice round, the M865, was developed. The M865 TPCSDS-T (Target Practice Cone Stabilized Discarding Sabot with Tracer) training round throws a 7.05 pound aluminum dart at 5577 f/s. (This round has very close to the same trajectory out to 2000 meters or so but a MUCH shorter maximum range than the M829 and can thus be safely fired on most tank ranges.) However, within its range it can still kill many armored vehicles quite handily and will reportedly go entirely through the older US M48 tank at 1200 meters.

The M829A3 round has just been type classified as the successor to the A2 version. It features a significantly heavier, 22 pound, composite material DU penetrator at 5200 f/s (reported as high as 5600 f/s in some publications) that will defeat even explosive reactive armor. It features a redesigned penetrator shape offering lower drag with better down range performance. Some performance details have "leaked" out. It gives approximately 30% greater penetration at 2 kilometers. Apparently pressures are such that some early M256 gun tubes have to be replaced in order to be able to handle the increased pressures.

|

|

M829A3 - Note the extreme length of the "dart." The dart is almost3 ft long |

The following information was extracted from sources in the public domain and will give an idea of the improvements made to the M829 family. The specific armor referenced is not specified, but in the table of ammunition properties the M829 series the performance of the M829A3 was close to twice that of the best tank gun rounds of all other nations.

| Round |

Armor Defeated |

| M829 | 64 |

| M829A1 | 71 |

| M829A2 | 81 |

| M829A3 | 93+ |

The tables below are from unclassified government firing tables for the M829 type rounds including the M856 training round. Data for the A1 & A3 variations was not available. Impressive rounds, eh?

| M829 Series Characteristics | ||||||

| M829 | M829A2 | M865 | ||||

| Range (Meters) |

Maximum Ordinate (Meters) | Velocity (m/s / f/s) |

Maximum Ordinate (Meters) | Velocity (m/s / f/s) |

Maximum Ordinate (Meters) | Velocity (m/s / f/s) |

| 0 | n/a | 1670 / 5479 | n/a | 1680 / 5512 | n/a | 1700 / 5577 |

| 500 | .1 | 1639 / 5378 | .1 | 1650 / 5414 | .1 | 1506 / 4941 |

| 1000 | .5 | 1608 / 5276 | .5 | 1620 / 5315 | .5 | 1326 / 4351 |

| 1500 | 1.0 | 1578 / 5177 | 1.0 | 1590 / 5217 | 1.4 | 1155 / 3790 |

| 2000 | 1.9 | 1547 / 5076 | 1.9 | 1560 / 5118 | 2.9 | 992 / 3255 |

| 2500 | 3.0 | 1517 / 4977 | 3.0 | 1530 / 5020 | 5.3 | 835 / 2740 |

| 3000 | 4.4 | 1487 / 4879 | 4.4 | 1500 / 4922 | 9.2 | 677 / 2221 |

| 3500 | 6.2 | 1457 / 4780 | 6.1 | 1470 / 4823 | 15.7 | 506 / 1660 |

| 4000 | 8.2 | 1427 / 4682 | 8.1 | 1440 / 4725 | 27.2 | 340 / 1116 |

| 4500 | 10.6 | 1396 / 4580 | 10.4 | 1409 / 4623 | 51.4 | 244 / 801 |

| 5000 | 13.4 | 1366 / 4482 | 13.2 | 1379 / 4525 | 101.3 | 187 / 614 |

| Angle of Fire (Degrees) |

Maximum Range (Meters) |

||

| M829 | M829A2 | M865 | |

| 5 | 21,894 | 22,464 | 5,791 |

| 10 | 29,392 | 30,261 | 6,545 |

| 20 | n/a | 42,998 | n/a |

| 30 | 58,995 | 61,515 | 7,473 |

| 40 | n/a | 90,812 | * |

| 50 | n/a | 113,627 | -- |

| 55 | 113,111 | 116,810 | -- |

| * Max range is 7,474 @ 31 degrees. | |||

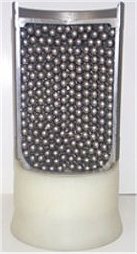

A recent, interesting development in 120 mm ammunition is the M1028 anti-personnel canister round which fires about 1100 tungsten balls of about 9 - 10 mm in diameter that would weigh between 115 and 155 gr each. Velocity is reported to be 1410 m/s (4625 f/s) and the round is effective up to between 500 and 700 meters. Individual pellet muzzle energy would be about 5700 ft/lb and at 700 yards about 280 ft/lb. I have a feeling that it would take out any helicopter within the lethal range. (Skeet shooting on a grand scale.) There is also a 105 mm version the M1040.

|

|

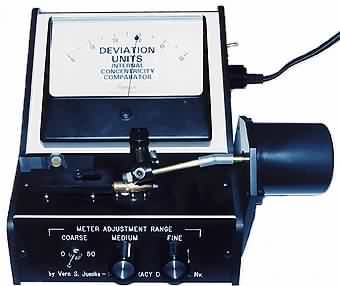

Q. How do you use a collimator to zero your rifle?

A. A collimator is a special optical device that is mounted to a firearm via a close fitting stud in the bore. It can be used to make a rough zero (there is no substitute for actually zeroing your firearm) or more properly to verify a previously made zero. When viewed though the sights it "projects" a target grid at infinity in line with the center of the bore. Most collimators have "4 inch" grid markings and the image you see is in reverse--that is left and up are really right and down.

Ideally you would want to adjust your sights (or cross hairs) to be centered on the collimator reticle. However, because the center of the bore is below the optical center of the collimator and we need to get the bullet's path up to the line of sight you actually need to be slightly below the center of the collimator's reticle.

In the graphic below the red cross hairs are the reticle of a scope superimposed on the grid for a test rifle. This particular rifle is probably shooting about 8 inches low and 12 inches to the left (remember, that the image is in reverse). If the cross hairs are adjusted to cover the green spot (about 4 inches "high" to compensate for the bore line and some bullet drop) the rifle will the impact very close to where it should and fine tuning should be easy. For more detailed information on zeroing visit the ballistics link on my home page. Due to various factors the "collimator zero" may not be exactly the actual zero, but unless you have a very strange barrel it should be close.

![collimator grid [3k gif]](colim.gif)

To use a collimator to verify that your actual zero hasn't changed, record the position of your actually zeroed sights on the collimator's grid. Then, to check that the zero hasn't be adversely "affected" by British Airways baggage folks just insert the collimator and ensure that the cross hairs are at your recorded position.

Q. What affects the accuracy of ammunition?

A. There are numerous factors that can influence the accuracy of ammunition, but uniformity is the key word. (We are talking about the ammunition itself and not any influences of the firearm.) Listed below in descending order of importance are the items that the bench rest shooters (the "all into one hole folks") have identified as having an affect on accuracy. Note, that while all of these things have an affect on accuracy there is a point of diminishing returns as 80 percent of the effort is needed to get the last 20 percent improvement. Simply paying attention to the basics will go a long way to improving your ammunition.

Bullet Quality - You can't get good results with junk. While some folks weigh their bullets of far more concern and influence is jacket thickness uniformity which affects bullet stability. Differences in jacket hardness and core hardness between bullet lots can effect velocity and subsequently accuracy.

However, jacket uniformity is the major difference between "hunting" bullets and "match" bullets. Weighing bullets can not tell you if an entire box was made from jackets with walls that are thin on one side. But, if the lead core is not perfectly centered "...arf of your bullets can fly wide in the ditch..." (with apologies to Rudyard Kipling). Modern commercial bullets are generally very uniformly made and will perform well in real world applications, and even "hunting" bullets can occasionally equal the performance of "match" type bullets. However, there is a lot of room for improvement when you are seeking that last tiny increment. The reason that bench rest shooters who are looking for the ultimate in accuracy buy bullets from specialty bullet makers who use highly uniform jacket material. The resulting consistency which exceeds that of commercially made "match" bullets provide that accuracy edge.

If you need the very highest accuracy possible the Juenke Internal Concentricity Comparator is what you need. While it doesn't actually x-ray your bullets, Vern Juenke's Internal Concentricity Comparator (I.C.C.) seems to. This device uses sonic pulses to look "inside" bullets for concentricity problems caused by voids and jacket irregularities. Consistent, uniform bullets are the secret to shooting those sub-moa groups at 1000 yards. If you do everything else correctly, and still get an occasional flyer, it may be your bullets. Top competitors with one of Vern's machine often use only 40% of the best hand swaged bullets for serious work. You may find only 10% of the less expensive or production bullets you have been using measure to "Golden BB" standards, with as many as 25% or more actually measuring as "junk". With run of the mill bullets is is possible, based on testing, to drop group size 1 moa or more. With high quality match bullets you can shrink group size up to an additional .2 and .75 moa depending on the bullet.

As an aside, even junk bullets may hold surprises. Last year while verifying a zero I fired a 1" 5 shot group from a Steyr Scout using my GI equivalent blasting load of surplus M80 Ball FMJ bullets and 42 gr of 4895 in LC cases, when normally this is a 2 to 3 MOA load. Wow! Out of curiosity I spun a bunch of those bullets on the ICC. While most swung the needle all over the place, out of 50 or so bullets a couple were really good. I can only surmise that the accuracy gods smiled on me that day and I picked 5 good bullets. Your mileage may vary but I was impressed with the possibilities.

This unit will also measure case wall uniformity. Tests have shown noticeable accuracy improvements if the cases are chambered with the thick or thin sides always in the same position.

|

|

|

|

|

|

|

|

| "Bad" bullet jacket thickness variance | "Good" jacket thickness variance | ||

| 15 graduations on the meter face is approximately .0003". | |||

The I.C.C. cost over $1200 and is out of production.. However, a lot were sold to serious shooters so you might be able to locate a used one.

Powder Type & Charge - One of the big factors affecting accuracy comes about from the barrel's vibration for a particular bullet weight. These vibration harmonics are caused by the bullet's acceleration and spin and are nearly constant for a given bullet weight. (However, different bullets of the same weight will give different velocities with the same powder charge due to differences in jacket hardness, length of bearing surface, gas seal due to base shape, and core hardness.) Selecting a powder type and charge weight that will put the bullet's velocity into the barrel's "sweet spot" (there are actually several "sweet spots") velocity range will keep the bullet's flight consistent.

Powders should be selected on their ability to nearly fill the case (which helps to ensure uniform ignition and burning) and their ability to safely reach the barrel's highest velocity sweet spot. It should be noted here that primers have an effect on pressure and velocity because of their effect on uniformity of ignition. Randomly changing primers can move your velocity out of the "sweet spot" so loads need to be developed using standardized components. (For a discussion of this sweet spot and how to find it using you chronograph see the "Load development" link on my home page.)

Case Capacity - Using mixed cases rather than cases sorted by unprimed weight will lead to erratic grouping performance. Sort your cases into batches of equal weight or groups not varying more than about 1/10 gr for smaller cases (.223 size) or 2/10 grain for .308/.30-06 cases

Neck Tension - Investigation has recently shown that neck tension (the case's grip on the bullet) can also have a big effect on accuracy. While the permissible variation is still being investigated it has been shown that widely varying neck tension has a drastic affect on group size. This is due to the effect of the force need to get the bullet moving and its effect on the burning characteristics of a powder--similar to the effect of varying the amount of bullet travel before the bullet engages the rifling. For those who crimp their bullets the same thing holds true. A uniform and consistent crimp results in better accuracy.

The traditionally method of controlling neck tension has been by annealing case necks, turning case necks to a uniform thickness, and monitoring the number of time a case is fired but actual force hasn't been checked. Some people have been using a bathroom scale, a bullet diameter arbor, and a drill press to attempt to measure neck tension. Southwest Products/RSI now offers a strain gauge device that can be put in your reloading press to measure neck tension accurately and easily using a device called a "compression" gage enclosed in a stainless steel anvil. It fits any single stage reloading or arbor press for measuring neck tension. For more details you can go to RSI's website by clicking here.

Speaking of crimping remember that use of a roll crimp requires that cases be trimmed to a uniform length or tension will vary. For crimping rifle cases pick up one of Lee's "factory crimp" dies. They can work wonders.

Seating Depth - Seating depth (related to the overall length of the assembled cartridge) affects the amount of free travel a bullet has before engaging the rifling and has an affect on pressure and velocity. Consistent seating depth helps to provide consistent performance. Ideally bullets should be seated so that they have only a few thousandths of an inch free travel before engaging the rifling but this consideration may need to be modified by the need to maintain overall length for magazine feeding. Changing bullets will have an effect here as different bullet profiles will yield a different amount of free travel for a given overall length. Overall length as related to seating depth needs to be measure from the bullet's ogive rather than the tip because tips can be crushed or flattened giving a false reading. Sinclair and other companies makes nifty devices to expedite this measurement. Also ensure that your seating stem presses on the bullet body and not the tip.

Consistency Of Flash Hole - A misshapen or burred flash hole alters the size and shape of the "flash" created by the primer which has an effect on the uniformity of ignition of the powder. Simply insuring that there are no burrs or blockages by using an inside flash hole deburring tool" will help to improve accuracy. If you notice that the flash hole itself is misshapen or seemingly over or undersized you should cull those case. Undersized flash holes can be uniformed with a #45 drill.

This also brings up the topic of flash hole eccentricity. Tests done some years ago by William C. Davis, Jr. for the NRA showed that if flash hole eccentricity was .020" or less the effect was less than .050" in group size at 100 yards if such cases were mixed with "normal" cases in a .30 caliber rifle.

Neck Uniformity - Case necks that are uneven in thickness will cause the bullet to engage the bore in an inconsistent manner due to the random positioning of the bullet. This will detract from accuracy. Necks can be uniformed with one of the neck reaming tools available from places like Sinclair. Care must be taken not to thin the necks too much, especially for cartridges to be used in magazine fed firearms.

Case Uniformity - This is primarily concerned with brass thickness and case wall uniformity. Case weight is related to case volume and case volume affects pressure and thus velocity. Cases should be sorted by headstamp (you can get nuts and worry about lot numbers too, but simply sorting by headstamp seems to be enough) although some folks group their cases into batches based upon 3/4 or 1 gr increments in weight. Uneven thickness of case walls affects accuracy too but its effect is generally only noticeable with ultra accurate firearms. Primer pocket depth can also affect accuracy because varying depth varies the uniformity of ignition. but again its effect is generally only noticeable with ultra accurate firearms.

Q. What is the difference between a roll crimp and a taper crimp?

A. There are actually three types of crimps, roll, taper, and stabbed. The purpose of all three types of crimp is to securely and uniformly hold the bullet in the cartridge case. With a roll crimp the case neck is literally rolled either into the bullet material or a groove in the bullet to secure it. To ensure even tensioning cases which are to be roll crimped need to be trimmed to a uniform length. Roll crimps are primarily used on cartridges that headspace on the rim or case shoulder.

The taper crimp is used primarily with cartridge that headspace on the case mouth with lead bullets. While it can be used to secure jacketed bullets this can lead to bullet distortion. With a taper crimp the mouth of the case a run into a die with a tapered opening that squeezes the diameter of the neck down enough to grip the bullet securely but still leaves enough metal to headspace on the chamber.

Stab or ring crimping, used only on jacketed ammunition, consists either several impressed dimples or a groove pressed into the case mouth by a collet. The crimp can either enter a groove on the bullet or can just be pressed into the bullet body (which distorts the bullet). It is primarily used on military or commercial heavy caliber hunting ammunition where rough handling may be encountered. It is the least conducive to accuracy.

|

| Crimp Types--L to R: No crimp, stab crimp, taper crimp, roll crimp |

Q. Can you suggest some reduced charge practice loads for my hunting rifle?

A. Experimentation has been done with IMR Trail Boss powder and the results are astounding. Trail Boss is a very bulky powder designed for the cowboy shooting crowd and their light loads. Loading is very simple--basically fill your rifle case to the base of the bullet you are using, weigh that charge and then use 70 percent of that as your load. For a copy of IMR's data page on this powder in PDF format click here.

For conventional powders, for cartridges with case capacities similar to the .308 and .30-06 (including most full sized military cartridges) simply loading 13 gr of Alliant Red Dot and use a bullet weight of from 100 - 168 gr which will give you a very accurate load at a velocity between 1300 - 2000 f/s. I've used the surplus bulk packed 147 gr M80 ball bullets with this load as an inexpensive plinking and youth training round. With the .30-30 try 7 - 9 gr of Red Dot. With the .30 cal magnum cartridges try using 24 - 28 gr of SR4759 and the same bullet weights. Unique can also be used successfully in the .308 and .30-06 as well as other similar cartridges. Try 10 gr of Unique in the 308 and 12 gr of Unique in the .30-06 with bullet weights from 150 gr -170 gr. Using 152 gr M2 ball pulled bullets in the .30-06 8.5 gr. of Bullseye will give youa velocity of about 1080 f/s. For the 7.62 NATO, 8mm Mauser, 7.65 Argentine, 7.7 Japanese or .303 British, reduce the charge of Bullseye by 1 full grain.

For a really inexpensive 25 yd plinking load try using a 0 buck shot pellet lightly lubed with Lee "Liquid Alox" and press fitted half way into the mouth of neck sized .30 cal cartridge on top of 3.0 gr of Bullseye. Because of the small charge you should elevate the muzzle before firing to move the powder next to the primer. A pound of Bullseye and a bag of 0 buck will keep you in plinking ammo for a long time. A variation on this load is made by using a 00 buck pellet seated on top of a .30 cal gas check and run through a .308 bullet swaging die on your luber/sizer. You can also use the 100 gr half- jacket "plinker" bullets on top of 4 to 5 gr of Bullseye.

You can also use 7 grs. of Bullseye or 8 grs. of Unique or SR7625 with a 150-gr. bullet in the .30-30 for a small game load. Increase 1 grain for .308 Win, and 2 gr for the .30-06.

With jacketed bullets you don't really want to go below about 1150 f.p.s. as you may stick a bullet in the bore with subsonic loads unless you lightly tumble the bullets in Lee Liquid Alox, diluted 50-50 with mineral spirits, and start with a really clean bore.

Minimum reduced loads with 55-gr. bullet in the .223 for 100% safe bore exit from an AR-15 are 4 grs. of Bullseye, 5 grs. of Unique, PB, Red Dot, or SR7625. You can use a lighter bullet such as 40-50 grs. no problem. In a Hornet these charges are a snappy load like a .22 WMR. For a quieter load you can reduce the charges a grain if you lubricate the bullets.

Increase these loads by 1 grain for the 7.62x39 with a 110-gr. carbine bullet, or even the 123-gr. bullets.

Another solution for reduced loads is to use cast bullets and the suggested starting loads in a cast bullet manual like Lyman's. If you have a rifle in .308 or .30-06 another option is to use one of the cartridge adapters available from http://www.mcace.com/adapters.htm . These will allow you to shoot .30 Mauser, .30 Luger, .30 carbine,.32 ACP, .32 Colt/H&R, and 7.62 x 39 Russian. I have played a lot with a .308 one in .32 ACP and while not as convenient as a real .308 cartridge it is very quiet and accurate and just the ticket for pot shooting or back yard pest elimination.

|

|

|

.308 Win / .32 ACP adaptor |

|

Q. Just how much accuracy is "enough?"

A: While a firearm that will put them all into one hole is certainly interesting (apologies to Towsand Wheelan) how much accuracy is really needed depends on three things: what you are trying to do; the maximum considered range; and the size of your intended target's vital zone. You also need to keep in mind that it is not the incredible group that you shot once, but the consistent ability of the firearm to group that is what we are concerned with. I've seen some real clunkers shoot an occasional incredible group but they can't do it on demand. I had a friend with an M94 Winchester that shot a 3 round .68 inch group once with factory ammo (I witnessed the group being fired). However he was never able to reproduce that performance and would normally get about 2" groups at 100 yards.

First we'll talk about those shooters I call "technical shooters" such as the bench rest fraternity and the long range prairie dog hunters. They tend to use equipment that sometimes stretches the definition of a "rifle" and they normally shoot from a bench even in the field. Their primary challenge (and enjoyment) is to get the smallest group size possible. If their rifles won't consistently produce 5 and 10 shot sub-half-minute-of-angle or below groups they consider the firearm worthless. They will expend all kinds of time and energy to obtain .05" less size in their groups. Considering that .01" can make or break a bench rest match and that the prairie dog hunter's target is 6 inches high with about a 1inch vital zone, and that they will often shoot at 400-600 yards. These folks need every last bit of accuracy they can get. These are the people who develop all the tricks for both firearms and ammunition to improve accuracy and it is to them that the rest of the shooting world owes a great debt. For the technical shooter very, very small(er) is better.

It should be noted here that a firearm that will shoot 1" 100 yard groups all day will most likely not be a 1 moa (2") shooter at 200 and further due to what is called the "morning glory effect" in which the group size opens up as range increases due to stability considerations with the bullets flight and spin induced drift. Therefore: a) 100 yard groups are impressive but essentially meaningless; and b) the longer the range of your intended target the better grouping ability is needed.

For the rest of us, while getting a smaller group size, is a good goal, there can be a point of diminishing returns. For a field rifle 1.5 to 2 moa groups (5 shot) are more than sufficient, and if you can get smaller groups you can rejoice. If not, don't shed any tears. This level should be easily attainable with decent ammunition and a properly set up rifle without much effort. Consider that the vital zone of most common big game is generally given as 6 to 8 inches and the torsos are generally about 18" we can see that a different standard of "accuracy" can be used. A pedestrian 2" gun can keep all its shots in the vital zone of most game at 300 yards (assuming the shooter is up to the task). If you don't handload try using different brands of ammunition to see what your rifle likes. If you hand load try the tips listed in the previous "accuracy" item above to fine tune your loads and also see the "Load Development" link on my homepage. You might be surprised at what your rifle can do and you can then have bragging rights (verifiable) to shame your shooting friends.

As an aside. A lot of the tests you see in magazines often use 3-shot groups in their accuracy testing. This can be deceiving, as statistically the fewer shots you fire the better your group will be. (Remember the old adage that if you want a one hole group you just shoot once?) Here is some statistical data to give you an idea of what number of shots does to group size. The table is based upon a 1" 3-shot group.

| Effect of Number Of Shots On Group Size | |

| Number of shots in group | Expected Group Size |

| 3 | 1 |

| 5 | 1.22 |

| 10 | 1.53 |

OK. So we've discussed the technical details, so what is the bottom line? The following table can be your guide to "how much is enough."

| Use | Expected Max Range | Accuracy Standard |

| Target / Sniper | To 1000 | < ½ MOA |

| Varmint | To 500+ | < MOA |

| Long Range Hunting | To 500+ | < MOA |

| Mid Range Hunting | To 300+ | < 2½ MOA |

| Short Range Dangerous game | To 150+ | < 4 MOA |

Please email comments to Fr. Frog by clicking here.

| Back to Q&A Index | Ballistics Main Page |

| Back to Fr. Frog's Home Page |

Disclaimer

As far as I know all the information presented above is correct and I have attempted to ensure that it is. However, I am not responsible for any errors, omissions, or damages resulting from the use or misuse of this information, nor for your doing something stupid with it. (Don't you hate these disclaimers? So do I, but there are people out there who refuse to be responsible for their own actions and who will sue anybody to make a buck.)

Updated 2018-01-28