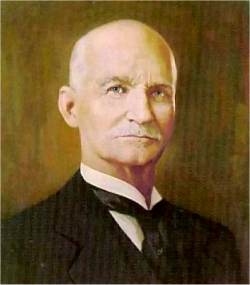

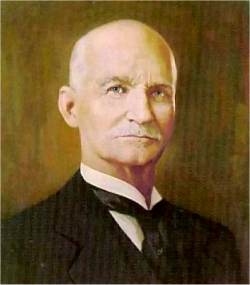

January 23, 1855 – November 26, 1926

John Moses Browning was perhaps the finest firearms designer, ever. His designs continue to work and to serve almost 100 years after they were created. There is an ongoing controversy about the reliability and safety of current 1911s vs. other "modern" pistols and I think this about sums the situation up.

January 23, 1855 – November 26, 1926

![]()

As translated from the original

ancient manuscripts by Fr. Frog.

©

copyright 2002, 2015, 2018 by John C. Schaefer

1 In the beginning was the 1911, and the 1911 was THE pistol, and it was good. And behold the Lord said, "Thou shalt not muck with my disciple John's design for it is good and it workith. For John made the 1911, and lo all of his weapons, from the designs which I, the Lord, gave him upon the mountain."

2 "And shouldst thou muck with it, and hang all manner of foul implements upon it, and profane its internal parts, thou shalt surely have malfunctions, and in the midst of battle thou shalt surely come to harm."

3 And as the ages passed men in their ignorance and arrogance didst forget the word of the Lord and began to profane the 1911. The tribe of the gamesman did place recoil spring guides and extended slide releases upon the 1911 and their metal smiths didst tighten the tolerances and alter parts to their liking, their clearness of mind being clouded by lust.

4 Their artisans did hang all manner of foul implements upon the 1911 and did so alter it that it became impractical to purchase. For lo, the artisans didst charge a great tax upon the purchasers of the 1911 so that the lowly field worker could not afford one. And the profaning of the internal parts didst render it unworkable when the dust of the land fell upon it, and these profaners didst try and fit more rounds of ammunition into the magazines than the holy number of seven, appointed for the .45.

5 And lo, they didst install adjustable sights, which are an abomination unto the Lord. For they doth break and lose their zero when thou dost need true aim. And those who have done so will be slain in great numbers by their enemies in the great battle. a

6 And it came to pass that the Lord didst see the abomination wrought by man and didst cause, as he had warned, fearful malfunctions to come upon the abominations and upon the artisans who thought they could do no wrong.

7 Seeing the malfunctions and the confusion of men, the lord of the underworld did see an opportunity to further ensnare man and didst bring forth pistols made of plastic, whose form was such that they looked and felt like a brick, yet the eyes of man being clouded, they were consumed by the plastic pistol and did buy vast quantities of them.

8 And being a deceitful spirit, the lord of the underworld did make these plastic pistols, filled with tiny springs and parts that were easily lostc, and they were unmenable to the artisans of earth so they were unable to muck much with the design, and lo these pistols did appear to function.

9 And the evil one also brought forth pistols in which the trigger didst both cock and fire them and which require a "dingus" to make them appear safe.

10 But man being stupid did not understand these new pistols and didst proceed to shoot themselves with the plastic pistol and with the trigger cocking pistols for lo their manual of arms required great intelligence which man had long since forsaken. Yet man continue to gloat over these new pistols blaming evil forces for the negligent discharges which they themselves had committed.

11 And when man had been totally ensnared with the plastic pistol, the lord of the underworld didst cause a plague of the terrible Ka-Boom to descend upon man and the plastic pistols delivered their retribution upon men. And there was a great wailing and gnashing of teeth in the land.

12 Then seeing that the eyes of man were slowly being opened and that man was truly sorrowful for his sinful misdeeds, the Lord did send his messengers in the form of artisans who did hear and obey the teachings of the prophet and who didst restore the profaned 1911s to their proper configuration, and lo, to the amazement of men they didst begin to work as the Lord had intended.

13 And the men of the land didst drive out the charlatans and profaners from the land, and there was joy and peace in the land, except for the evil sprits which tried occasionally to prey on the men and women of the land and who were sent to the place of eternal damnation b by the followers of John.

a Several old manuscripts add the following text. "And they [also rendered as "these men"] didst chamber it for cartridges who's calibers startith with numbers less than the Holy Number 4. And lo the Lord did cause great grief amongst these men when their enemies who were struck in battle with these lesser numbers didst not fall but did continue to cause great harm."

b or Hell

c recent addition based on a recently discovered manuscript

© copyright 2002 - 2018 by John C. Schaefer

For the faithful, the "feast day" of St. John Moses Browning is January 23.

For some more interesting information on John Browning see http://weaponsman.com/?p=10789

While the above was intended to be (slightly) humorous it really is the truth. Old John Browning really knew his stuff and his tolerances and his selection of various alloys for specific parts were well thought out. Nowadays, with "modern" pistols the use of a plethora of easily lost itsy-bitsy pins and springs in the design, and use of metal injection molding (MIM) parts is rampant. While they can be very rugged, the quality of MIM parts depends on how much care is utilized in their manufacture, something that is not often up to snuff, and their hardness is usually just on the surface. Smoothing the parts can frequently cut through the surface hardness. Also consider that an average user can completely disassemble a stock 1911 without any tools, while many of the "new" designs can only be completely disassembled by an armorer with special tools, inside of a bag to prevent loss of tiny pins and springs.

As to those tests that miraculously show how "bad" the 1911 was compared to some "modern" design, I personally know of several (including the government one that brought us the M9 Berretta) that were deliberately rigged by using very worn, out of spec 1911s and magazines, against tuned, hand selected other pistols. The 1911 served in 4+ wars with reliability and distinction. Why is it suddenly no good and unreliable? Hmmmm? To sell new models, that's why.

|

... But it's an outdated design "Of course the 1911 is an outdated design. It came from an era when weapons were designed to win fights; not to avoid product liability lawsuits. It came from an era when it was the norm to learn how your weapon operated and to practice that operation until it became second nature; not to design the piece to the lowest common denominator. It came from an era in which our country tried to supply its fighting men with the best tools possible, unlike today, when our fighting men and women are issued hardware that was adopted because of international deal making or the fact that the factory is some well-connected congressman's district. Yes, beyond a shadow of a doubt the 1911 IS an outdated design ... and that's exactly what I like about it." -- Rosco Benson |

Of course there can be another reason. In the name of "super accuracy," many of the modern 1911 variations and custom pistols are made way too tight especially in the slide to frame and bushing to slide fit, and many custom barrels have very tight chambers. I have seen one "name brand" 1911 with a chamber so tight that you could barely get new, min spec ammo to chamber and reloads generally would not chamber. One big name 'smith is notorious for guns so tight that on new pistols the slides stick when manually cycled until they have worn in. A tight slide to frame fit really isn't needed for accuracy. As long as the barrel to slide lock-up is consistent the pistol will shoot where it is pointed and shoot small groups. However, if tested in a Ransom rest which mechanically holds the pistol by the frame, they don't appear to group well since the slide is not held consistently in the same place on the frame. However, when held in the hand and sighted they group just fine.

Speaking of grouping, unless you are a national championship level bullseye shooter trying to eke out the very last decimal point in group size you don't need a tight chamber and overly tight tolerances. The same goes for the barrel bushing. Having it fitted to the slide so tightly that it requires a major effort and special tools to remove accomplishes nothing that can't be done with a fit that can be removed by hand or in the worst case by using a magazine base plate for leverage. In the real world hitting the second button down or hitting somewhere next to it doesn't matter, but if your pistol malfunctions it matters a lot!

Even a "rack" grade GI pistol will out shoot all but the best marksmen. As a case in point back in the mid-70s Tom Campbell, then of S&W, came to my club and shot an IPSC match using a non-selected, loose, GI 1911 (not an A1) with issue sights. He easily won the match by about 15 points shooting against folks with expensive custom pistols. It's the shooter, not the gun!

|

|

Two bad trends, IMHO, are the current fad of using Allen screws or Torx head screws on the 1911, and the use of square profiled hammer struts. With original spec'd parts no tools are needed to detail strip the 1911. The shaft of the safety can be used to push out the mainspring housing pin, the hammer strut can be used to drift out all remaining cross pins, and the lips on the sear spring can be used to remove the grip screws and magazine catch latch. (As an historical aside, the original grip screws had a wide radiused slot and were designed to use the rim of a cartridge for removal.)

While you shouldn't need one, if you are enamored with full length guide rods be sure you use one that does not require any tools to disassemble the pistol.

If you want to return your commercial 1911 to close to JMB's original standards, Brownells has the parts. (The PN are for blued steel parts.)

| Magazine catch lock (slotted head) | 965001153 |

| GI Recoil spring guide | 634000006 |

| Recoil spring plug | 206000042 |

| Hammer strut (round profile tip) | 087823000 |

| Slotted grip screws (blue set of 4) | 080569004 |

| Series 70 (GI style) firing pin | 047000019 (Use to deactivate the Kimber "Schwartz" firing pin "safeties) Note that the illustration on Brownells site is not the correct pin (as of 7/18/12) but this part number will get you a "GI"/S70 type firing pin. |

| Lanyard Loop | 849000021 |

| Main Spring Housings w/loop | 849000005

(Flat) 849000015 (Arched) |

| "Diamond" pattern walnut stocks | 078000148 |

Brownells also carries a large assortment of machined extractors, sears, disconnectors, firing pin stops, and hammers if your parts are MIM.

For

original pattern grip screws that can be turned with a cartridge rim

10-8Performance.com offers them at

http//www.10-8performance.com/grip-screws-gi-pattern-set-of-4-stainless/.

Unfortunately, they only offer them in stainless steel now so you'll have to

"blacken" them yourself.

If the extractor is properly shaped and tension is properly set, if someone hasn't mucked with the internals, if there are no burrs or razor edges internally, and the magazines aren't crap, they'll work every time. When I was active in competition I had a 1911 that went close to 150,000 rounds (Yes that is correct--it was used by several people all the time.) without a single malfunction using both ball and semiwadcutter ammo), at which point I stopped keeping track of things. The only thing ever done to it was to replace the recoil spring once a year (if I remembered to do it), and keep it cleaned and properly lubed. The extractor was replace at around 80,000 rounds when a small nick was discovered. I sold it to a friend and as far as I know it is still running.

The one non-JMB change that seems to be good is the use of the "18 lb" recoil spring in place of the GI spec 16 pound spring and the heavier firing pin return springs, especially with today's hotter loads. With modern loadings the 18 pound spring gives a smoother cycling of the action while still functioning with most non spec ammo and the heavier firing pin spring makes sure the firing pin returns properly.

Speaking of magazines. If you want the best magazine available you should check out Tripp Research's Cobramag. These 7 (and available 8 round magazines-forshame) are probably the only real improvement made to JMB's design since 1911. They hold the top cartridge slightly higher than the original magazines and give smoother feeding with modern flat point and JHP ammunition. The magazines run about $35 each and are available directly from Tripp Research. These magazines get 5 Flippers from Fr. Frog. The only problem I have ever heard of with these magazines is that they fit tight in some frames that have out of spec mag wells. They also offer follower upgrade kits to upgrade conventional 7 rd magazines.

|

The solid floor plate, flush fit magazines that had previously been dropped are now back in production. Their web site is www.trippresearchinc.com and their phone number is 432-837-9445. Talk to Virgil Tripp and tell him that ol' Fr. Frog sent you from his web site.

Photo courtesy of Tripp Research and used with their permission.

Please email comments to Fr. Frog by clicking here.

| Back to Fr. Frog's Homepage |

Updated 2020-05-26